Articles

Navigating supply chain strategies amid global uncertainty: just-in-time vs. just-in-case

In the wake of significant global disruptions—ranging from the enduring impacts of the COVID-19 pandemic to geopolitical tensions, climate variability, technological advancements and economic uncertainties—manufacturing companies are confronted with a…

In the wake of significant global disruptions—ranging from the enduring impacts of the COVID-19 pandemic to geopolitical tensions, climate variability, technological advancements and economic uncertainties—manufacturing companies are confronted with a dilemma: How should they structure their supply chains to thrive in this era of heightened unpredictability?

Should they lean towards the efficiency of Just-in-Time (JIT), adopt the security of Just-in-Case (JIC), or strike a delicate balance between both strategies? Finding the optimal equilibrium between JIT and JIC has emerged as a critical imperative across industries.

Despite contrasting viewpoints advocating for either JIT or JIC, the urgency of making a well-informed decision promptly is clear. There are several key considerations when selecting the appropriate supply chain strategy:

1.Value of Stock: Whether high-value or low, stock valuation dictates the financial implications of tying up capital in inventory.

2.Complexity of Product: The intricacy of products influences production schedules, inventory management and the feasibility of JIT or JIC approaches.

3.Volatility of Demand/Understanding of Demand: Predicting demand fluctuations in minimising inventory costs while ensuring sufficient stock availability.

4.Supply Chain Reliability and Risk Tolerance: The resilience of the supply chain and the company’s tolerance for risk play important roles in selecting JIT or JIC.

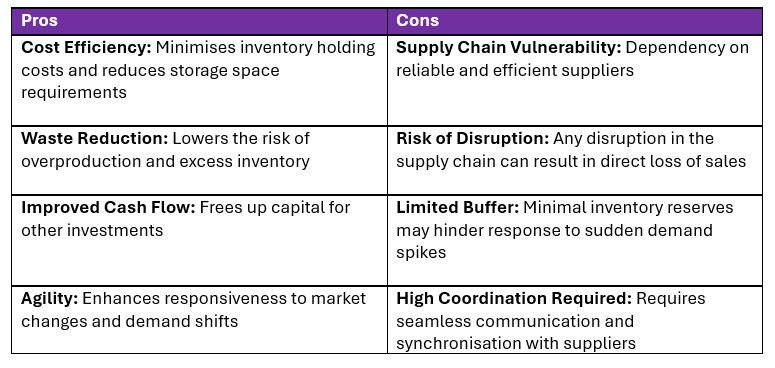

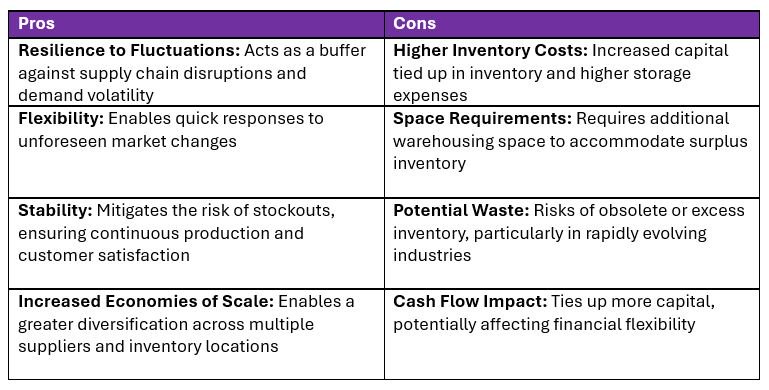

Pros and cons of JIT vs. JIC supply chain strategies:

Just-in-Time (JIT)

Just-in-Case (JIC)

The role of emerging technologies

Both JIT and JIC supply chain strategies have their respective pros and cons. Over the last few years many organisations have suggested that JIT only worked well for businesses due to stable trade conditions and robust logistics capabilities. Hence, the sentiment for many organisations to change their models during times of uncertainty due to the heavy reliance on global supply chains. Disruptions such as wars and geopolitical tensions have temped many companies into the idea of abandoning JIT in favour of JIC.

However, the emergence of many new technologies has increased the reliability of JIT to ensure that despite unpredictable global supply chains the model runs smoothly.

Technologies such as analytics, blockchain, IoT and AI can be leveraged to design and operate a ‘revamped’ version of the traditional JIT model. Analytics can help members of the supply chain identify common parts across product lines and design optimal buggers. Digital twins, which are digital models of the supply chain, can alert downstream plans about potential upstream disruptions quickly allowing them to utilise buffers effectively. Additionally, Blockchain can be used to create more security around sharing information among supply chain members.

Leveraging these technologies is crucial for managing uncertainty and ensuring the reliability of the model. However, their effectiveness hinges on the organisation’s data and associated data capabilities. For these technologies to be truly effective, the data must be of high quality, accurate and up to date, integrated from various sources including suppliers and logistics partners. Additionally, the right software tools are essential for processing and analysing this data effectively. Employees must be trained to use these tools and interpret the data correctly, while consistently adhering to data management practices.

How and why supply chain strategies are changing

1.Global Disruptions: Events such as the COVID-19 pandemic, geopolitical tensions, climate change, and economic uncertainties have exposed the vulnerabilities in traditional supply chain models. These disruptions have made it clear that relying solely on Just-in-Time (JIT) strategies can be risky due to their dependence on stable and predictable conditions.

2.Technological Advancements: New technologies such as analytics, blockchain, IoT, and AI are transforming supply chain management. These technologies can enhance the reliability of JIT by improving real-time data sharing, predictive analytics, and supply chain visibility.

3.Risk Management: Companies are increasingly recognising the need to balance efficiency with resilience. This has led to a shift towards Just-in-Case (JIC) strategies, which provide a buffer against supply chain disruptions but come with higher costs and inventory requirements.

Important actions for companies

1.Evaluate Stock Value: Companies need to assess the financial implications of their inventory. High-value stock might justify a JIC approach to avoid stockouts, while low-value stock might be better managed with JIT to minimise holding costs.

2.Understand Product Complexity: The complexity of products affects production schedules and inventory management. Companies should tailor their supply chain strategies based on the intricacy of their products.

3.Predict Demand Volatility: Accurate demand forecasting is crucial. Companies should invest in advanced analytics to predict demand fluctuations and adjust their inventory levels accordingly.

4.Enhance Supply Chain Reliability: Building a resilient supply chain involves assessing the reliability of suppliers and logistics partners. Companies should diversify their supplier base and develop contingency plans for potential disruptions.

5.Leverage Technology: Implementing technologies like digital twins, blockchain, and AI can help companies create a more responsive and secure supply chain. These tools can provide real-time insights and enhance coordination among supply chain partners.

6.Invest in Data Capabilities: High-quality, accurate, and up-to-date data is essential for leveraging new technologies effectively. Companies should ensure they have the right software tools and trained personnel to manage and analyse this data.

Companies that can effectively integrate technology and data management into their supply chain strategies will be better positioned to navigate uncertainty and thrive in the long term.

Discover how we help clients stay ahead of the game: